Waste management

Circularity and value creation

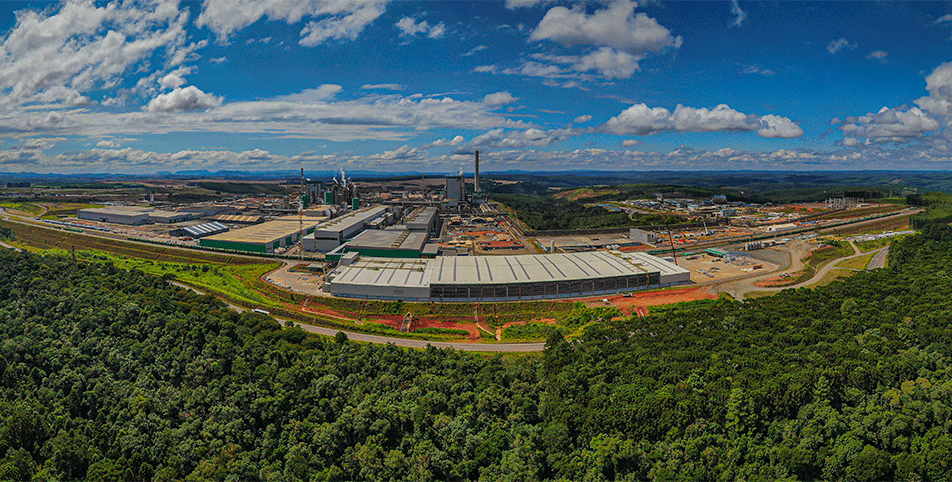

Waste management is a priority item on Klabin's sustainability agenda. The Company's 2030 target is to zero the disposal of industrial waste to landfills. In addition to human activities, the company's operations generate solid waste as a result of the byproducts of the production processes. Therefore, by leveraging intelligent use of natural resources, Klabin employs technology to enhance circularity in processes, thereby creating value across the entire supply chain.

Refuse, reduce, reuse, repurpose, recycle – the concept of the "5 Rs" of sustainability – are daily practices in the company's activities. Once sorted, all packaging materials received from suppliers are disposed of in an environmentally appropriate manner. The same is true for sludge from the Water Treatment Plants (ETAs) and Effluent Treatment Plants (ETPs), ash and bark, solid waste generated in operations, as well as other recyclable material.

The Company's waste management is governed by internal policies and guidelines, as well as federal, state, and municipal legislation (such as Law No. 12.305/2010 – National Policy on Solid Waste). These regulations are constantly monitored and accompanied by actions that demonstrate compliance with standards.

98.5%

was Klabin's industrial waste reuse rate in 2022, up 0.4 percentage points compared to 2021.

99.8

was the rate of waste reuse achieved by the Puma Unit in 2022, a result driven by the performance of the Waste Processing Center, which had been in operation since the start.

What is already done in the Company

-

Disposal of dregs and grits (waste from chemical recovery) for co-processing and use in agriculture as a soil corrector, and in the production of materials for civil construction, such as pavers and bricks.

-

Production of tall oil from the soap generated in wood cooking processes, to be used as a clean energy source, thereby reducing the consumption of oil as fuel.

-

Working with customers to recover post-consumer materials, such as the reverse logistics and paper waste recycling project, where the materials return to the consumer chain as new packaging for different segments and sectors of the economy.

-

Representativeness in the sector through participation in institutions such as the Brazilian Tree Industry (Ibá) and the Corporate Commitment to Recycling (Cempre), which foster discussions on trends and legislation.

-

Initiatives to support the Public Authority for the improvement of selective collection in municipalities where Klabin operates, such as the Solid Waste Program in Paraná.

-

Use of by-products of wood processing, such as bark and residual biomass, in energy production.

Waste is used to manufacture bricks

In a project developed by Klabin's Technology Center in collaboration with the Ceramic Technology Center (NTC), dregs and grits (byproducts from Klabin's chemical recovery operations) are used as raw materials to produce ceramic bricks. In the pilot phase, the initiative was developed in the Paraná cities of Sapopema, Curiúva and Arapoti, and in Goiana (PE). A total of 95,000 bricks were produced, benefiting public works and local institutions of these municipalities.

Initiatives that promise to make a difference

Initiatives that promise to make a difference

Klabin at the Bienal do Lixo

In May 2022, Klabin took part in the inaugural edition of the São Paulo Bienal do Lixo [Trash Biennial], held at Villa Lobos Park. Visitors had the chance to experience the "Sustainable Journey", an interactive action that sought to promote reflection on each citizen's environmental responsibility. The public was also introduced to the KlaCup Bio, a biodegradable solution for paper cups. The Company's executives also participated in panels throughout the event.

About 10,000 people participated in the Sustainable Journey.

1,400+ messages were sent from the public about what sustainable commitment they intend to make.

What still challenges Klabin

Even with a 98.5% rate of industrial waste reuse, Klabin is not content and continually assesses potential opportunities. Finding a technically sound and economically feasible solution for waste generated from paper recycling, grits, dregs and terciary sludge remains a challenge for the Company, which maintains a research line dedicated to finding alternatives to landfills for the disposal of industrial waste.