R&D and Innovation

Research, development and innovation

Work in the present to build the future. With this vision, the Research, Development, and Innovation team's performance is directly connected to Klabin's growth strategy and sustainable outlook, helping to increase the Company's competitiveness.

Whether it be in increasing forest productivity, enhancing industrial processes, developing multi-purpose products that are renewable, recyclable, and biodegradable, or managing impacts on the value chain, investments in R&D+I, which totaled BRL 63.9 million in 2022, have been essential.

Managing the impacts of its operations continually challenges Klabin and its R&D+I area to focus on creating value in the circular economy chain.

Performance focused on new opportunities in:

-

Improvement or creation of processes.

-

Product development.

-

New applications for the products that the company manufactures.

-

Development to meet customer needs.

-

Contribution to the circular economy.

Technology Center

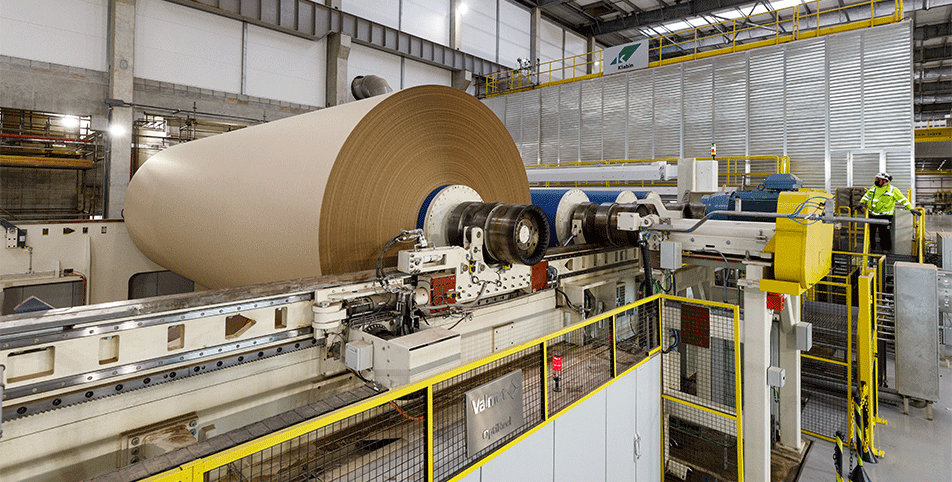

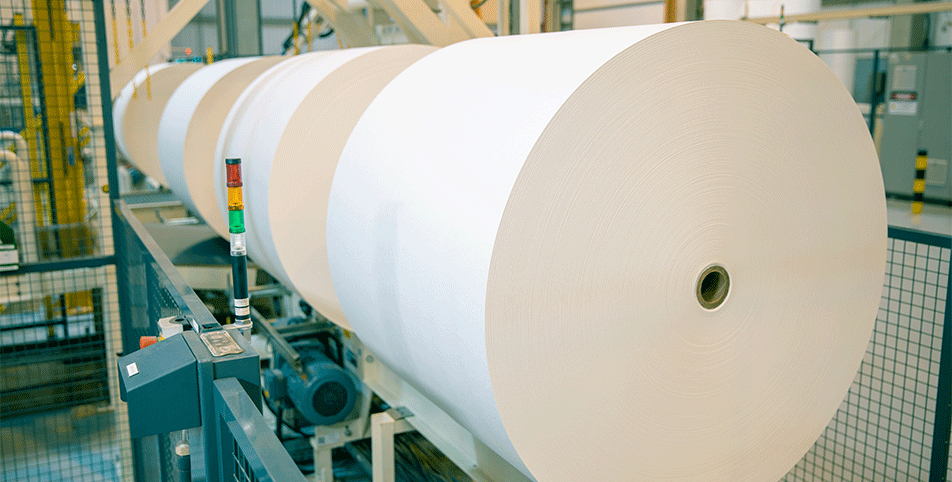

The Klabin Technology Center (CTK) in Telêmaco Borba (PR) completed five years of operation in 2022, transforming the relationship between the Company's industrial and forestry areas. CTK provided the company with a robust structure to replicate processes, simulate manufacturing, and expedite product development.

Industrial development

focused on incrementally improving Klabin's portfolio products and refining processes.

Forest development

focused on incrementally improving Klabin's portfolio products and refining processes.

Research

to add barrier properties to paper, always focused on protecting human health and consumption.

Innovative solutions that were born at CTK

In 2022, a partnership with the Chemical and Textile Industry Technology Center (SENAI CETIQT) resulted in a project to develop an antiviral coating for application on kraft paper, composed entirely of organic components and free of any metals. The coating is primarily designed for e-commerce packaging and has already undergone research and efficacy tests to deactivate the coronavirus (SARS-CoV2) conducted by Bio-Manguinhos/Fiocruz, one of the most highly regarded organizations in the country in the development of immunobiologics.See below other innovations developed at the Klabin Technology Center.

The customer experience at Klabin

With the opening of the Packaging Technology Center (CTE) in 2022, Klabin will strengthen the customer's experience of being immersed in the Company's culture of innovation and enhance the product co-creation processes. With the goal of becoming an experiential center, the new structure is in the Jundiaí Tijuco Preto Unit, in the interior of São Paulo.

CTE aggregates a portfolio of projects in collaboration with customers from multiple industries, to address a variety of challenges. Some examples include: packaging for transporting and protecting furniture, adding new functionality for reuse; the sack kraft paper bag model laundry bag for packaging uniforms in factory operations; and the development of a new concept in packaging for paints and optimization of the production process.

The latter is already being produced by Klabin at the Suzano Unit (SP). The packaging, made of corrugated cardboard, is designed for Suvinil's line of water-based varnishes and replaces the tin packaging. The product is packaged in a plastic bag made of 100% virgin material, and enclosed in a cardboard box. Easy to handle, 100% recyclable, and with a lower environmental impact than metal gallons, emitting less CO2, the product meets the customer's demand for a more practical and sustainable packaging than the previous one.